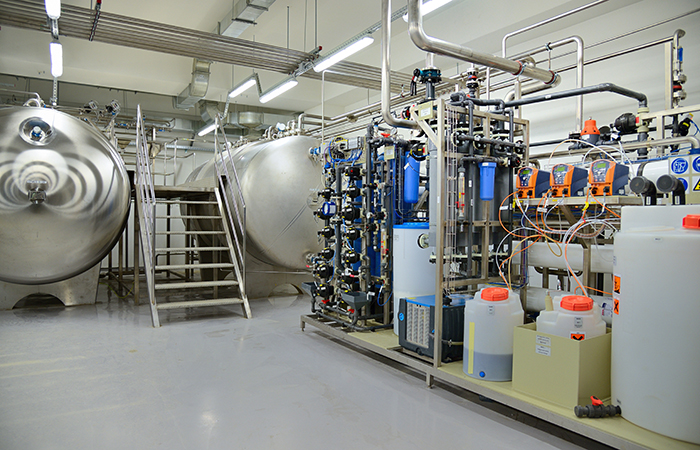

Dosing systems

- Water technologies >

- Technological engineering >

- Process water treatment >

- Dosing systems

In technological processes, it is necessary to dose the active component, which can be in various forms:

- solid (powder or crystals)

- paste

- liquid

- gas

The following are dosed in the form of powder or crystals:

- lime for the preparation of the milk of line

- activated carbon for "inline" removal of organic matter from water

- polyelectrolyte powder for the preparation of flocculant solution

For dosing, auger dosers are used with one or more parallel augers.

Additives in the rubber industry are dosed in the form of a paste. Preheating is often required. Auger pumps are used for dosing.

The following are dosed in the form of liquid:

- odium hypochlorite solution for the disinfection (chlorination) of water (drinking water, pool water)

- solutions of active substances to prevent limestone deposition and corrosion in cooling and heating systems

- solutions of biocidal products to prevent the growth of microorganisms

- solutions of chemicals for washing membrane systems

- solutions of ionic resin regeneration agents

Membrane dosing pumps are most suitable for dosing. In some cases, peristaltic or screw pumps are also useful. A pump is the "heart" of the dosing system. In addition to the pump, there are also storage tanks, suction filters, non-return valves, pipelines, washing connections, dosing valves, flow controls and pulsation dampers.

In the form of a gas, gas chlorine is dosed for chlorinating drinking or pool water.

Dosing systems

Contact us

Together we can find a solution